Battle of the Build Plates: Comparing Bambu Lab SuperTac, BIQU Frostbite, and BIQU Glacier

Choosing the right build plate is key to 3D printing success. This guide compares Bambu Lab SuperTac, BIQU Frostbite, and BIQU Glacier, highlighting their strengths in adhesion, durability, energy efficiency, and material compatibility to help you find the perfect match for your printing needs.

When it comes to achieving perfect 3D prints, the build plate plays a pivotal role in ensuring proper adhesion, minimizing warping, and supporting diverse filament types. Whether you're printing intricate PLA designs, durable PETG parts, or advanced engineering materials like ABS and nylon, selecting the right build plate can make all the difference.

In this article, we dive into a detailed comparison of three popular options—Bambu Lab SuperTac, BIQU Frostbite, and BIQU Glacier—to help you determine which one best suits your printing needs. From adhesion performance to material compatibility and energy efficiency, we'll break down the key features, pros, and cons of each plate so you can make an informed choice for your 3D printing projects.

Why Build Plates Matter in 3D Printing

The build plate is more than just a surface for your prints—it’s a critical component that directly impacts print quality, success rates, and even energy efficiency. A good build plate ensures strong adhesion during printing, preventing issues like warping or detachment that can ruin a project. It also provides a stable foundation for various filament types, from beginner-friendly PLA to high-performance materials like nylon and TPU.

However, not all build plates are created equal. Factors like material compatibility, durability, ease of cleaning, and energy requirements vary significantly between options. Choosing the right build plate depends on your specific needs, such as the types of filaments you use, the complexity of your designs, and your budget. In this comparison, we’ll explore how the Bambu Lab SuperTac, BIQU Frostbite, and BIQU Glacier perform across these essential criteria to help you find the perfect match for your 3D printing setup.

Overview of the Build Plates

Let’s start by introducing the three contenders in this comparison: Bambu Lab SuperTac, BIQU Frostbite, and BIQU Glacier. Each of these build plates is designed with unique features and strengths, catering to different types of users and printing requirements.

- Bambu Lab SuperTac: Known for its exceptional adhesion, this build plate is optimized for PLA and PETG filaments. It stands out for its energy efficiency, requiring low bed temperatures to achieve strong bonding. Its tacky surface ensures durability even after extended use, making it a reliable choice for consistent prints.

- BIQU Frostbite: A cost-effective option with excellent performance for PLA and PETG, Frostbite offers strong magnetic hold and adhesion at room temperature. Its slightly textured surface provides a glossy finish, while its energy-efficient design makes it ideal for users looking to save on heating costs.

- BIQU Glacier: The most versatile of the three, Glacier supports a wide range of materials, including ABS, TPU, and nylon. It features a lightly textured matte surface and excels in warpage resistance, making it an excellent choice for advanced materials and engineering-grade projects.

These build plates cater to different priorities—whether it’s energy savings, material versatility, or cost-effectiveness.

Key Features of Each Build Plate

To understand how these build plates stack up, let’s take a closer look at their standout features and what makes each one unique.

Bambu Lab SuperTac

The Bambu Lab SuperTac is designed for users who prioritize strong adhesion and energy efficiency. Its tacky surface ensures excellent bonding for PLA and PETG filaments, even at lower bed temperatures (35–45°C). This not only reduces energy consumption but also minimizes the risk of warping during prints. The plate is double-sided, offering extended durability, and retains its adhesive properties even after extensive use. Cleaning is simple—just water and mild detergent will do the trick. However, its relatively thin steel plate requires careful handling, and it comes at a higher price compared to alternatives.

BIQU Frostbite

The BIQU Frostbite is a budget-friendly option with impressive performance for PLA and PETG. Its textured surface provides strong adhesion at room temperature or with minimal heating, making it an energy-efficient choice. The magnetic hold ensures stability during printing, while its durable coating resists wear and tear over time. Cleaning is versatile—users can opt for water, detergent, or alcohol to maintain the plate’s surface. It’s also compatible with popular printers like the Bambu Lab X1, P1, and A1 series. While it doesn’t support advanced materials like TPU or ABS, it’s a reliable option for standard filaments.

BIQU Glacier

The BIQU Glacier stands out for its versatility, supporting a wide range of materials such as ABS, TPU, and nylon. Its lightly textured matte finish provides decent adhesion without being overly tacky, making it ideal for engineering-grade filaments that require precision. The plate is double-sided with a uniform finish and excels in warpage resistance, ensuring consistent performance even after prolonged use. It includes a convenient grip handle for safe removal when hot. While it’s less effective for PLA and PETG compared to the other two plates, its broad material compatibility makes it the go-to choice for advanced applications.

Each build plate offers distinct advantages depending on your printing needs.

Performance Comparisons

Now that we’ve outlined the key features of each build plate, let’s compare their performance across critical metrics to see how they measure up in real-world use.

Adhesion

- Bambu Lab SuperTac: This plate excels in adhesion, especially for PLA and PETG. Its tacky surface ensures strong bonding even at lower bed temperatures, reducing the likelihood of warping or detachment during prints. It’s ideal for users who need consistent results for standard filaments.

- BIQU Frostbite: Offering excellent adhesion at room temperature or minimal heating, Frostbite is a strong contender for PLA and PETG users. Its textured surface provides a glossy finish, but it slightly lags behind SuperTac in overall bonding strength.

- BIQU Glacier: While it doesn’t match the adhesion levels of SuperTac or Frostbite for PLA and PETG, Glacier performs well with engineering-grade materials like ABS and TPU. Its lightly textured matte finish is better suited for advanced filaments that require less tackiness.

Durability

- All three plates are double-sided and built to withstand wear over time. The SuperTac maintains its tacky surface even after extensive use but requires gentle handling due to its thinner steel plate. The Frostbite features a robust coating that resists wear and can be easily restored with cleaning. The Glacier, with its uniform finish and multi-layer composite structure, offers exceptional durability, especially for advanced materials.

Energy Efficiency

- SuperTac leads in energy efficiency, as it achieves strong adhesion at lower bed temperatures (35–45°C), making it an excellent choice for energy-conscious users.

- Frostbite is also highly efficient, often eliminating the need for bed heating entirely when printing with PLA or PETG.

- Glacier performs well without significant heating for some materials but may require moderate heat (40–55°C) for advanced filaments like ABS or nylon.

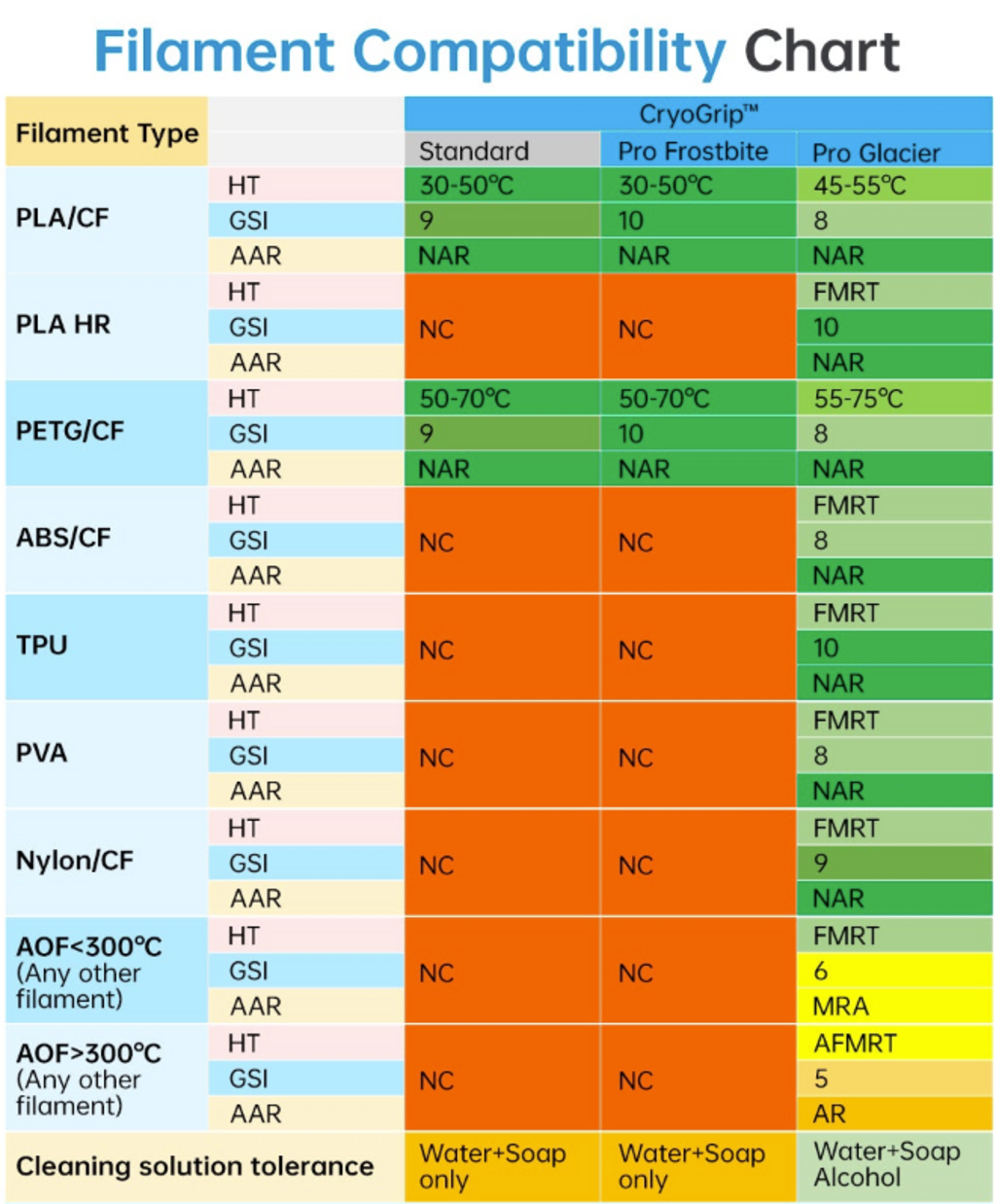

Material Versatility

- SuperTac and Frostbite are optimized for PLA and PETG but have limited compatibility with other materials like TPU or ABS.

- Glacier stands out as the most versatile option, supporting a wide range of filaments, including engineering-grade materials such as nylon and TPU. This makes it the best choice for users working on complex or high-performance projects.

By evaluating these metrics, it’s clear that each build plate caters to different priorities.

Pros and Cons of Each Build Plate

To help you make an informed decision, here’s a detailed comparison of the advantages and disadvantages of each build plate, summarized in a table for clarity.

| Build Plate | Pros | Cons |

|---|---|---|

| Bambu Lab SuperTac | - Exceptional adhesion for PLA and PETG, even at low temperatures. | - Higher price point compared to alternatives. |

| - Energy-efficient, reducing power consumption during prints. | - Thin steel plate requires careful handling to avoid bending or damage. | |

| - Durable tacky surface that maintains performance over time. | - Limited material compatibility (not suitable for TPU or PLA Silk). | |

| BIQU Frostbite | - Strong adhesion at room temperature or with minimal heating; highly energy-efficient. | - Limited to PLA and PETG; not compatible with advanced materials like ABS or TPU. |

| - Affordable alternative to SuperTac with excellent durability. | - Slightly less effective adhesion compared to SuperTac for standard filaments. | |

| - Easy to clean with water, detergent, or alcohol. | ||

| BIQU Glacier | - Most versatile option, supporting materials like ABS, TPU, and nylon. | - Less effective adhesion for PLA and PETG compared to SuperTac and Frostbite. |

| - Superior warpage resistance and durability, even after extended use. | - May require moderate heating for certain materials, reducing energy efficiency slightly. | |

| - Includes a convenient grip handle for safe removal of the hot plate. |

Summary

- The Bambu Lab SuperTac is the best choice if you need exceptional adhesion and energy efficiency for PLA and PETG, but are willing to invest in a premium product.

- The BIQU Frostbite is a cost-effective option that balances strong adhesion and durability for standard filaments, making it ideal for budget-conscious users.

- The BIQU Glacier stands out as the most versatile option, excelling in advanced material compatibility and durability, perfect for users working with engineering-grade filaments.

Ultimately, your choice will depend on your priorities—whether it’s cost savings, energy efficiency, or material versatility. By understanding the strengths and limitations of each build plate, you can make an informed decision that aligns with your printing goals. Happy printing!