Mastering ABS 3D Printing Without an Enclosure: Tips and Tricks

How to Print ABS Successfully Without an Enclosure: A Complete Guide

3D printing with ABS can be a rewarding experience, offering durability and strength for various applications. However, traditional methods often require enclosures to prevent warping due to temperature fluctuations. This article explores how you can successfully print ABS without an enclosure, leveraging tips and tricks to achieve professional results. A Bambulab A1 or Bambu A1 Mini are well choices to print ABS when we manage to overcome the missing enclosure. Especially when you are not printing ABS regularly, this is a cheap alternative to buying an enclosed printer in addition.

The Challenges of Printing ABS Without an Enclosure

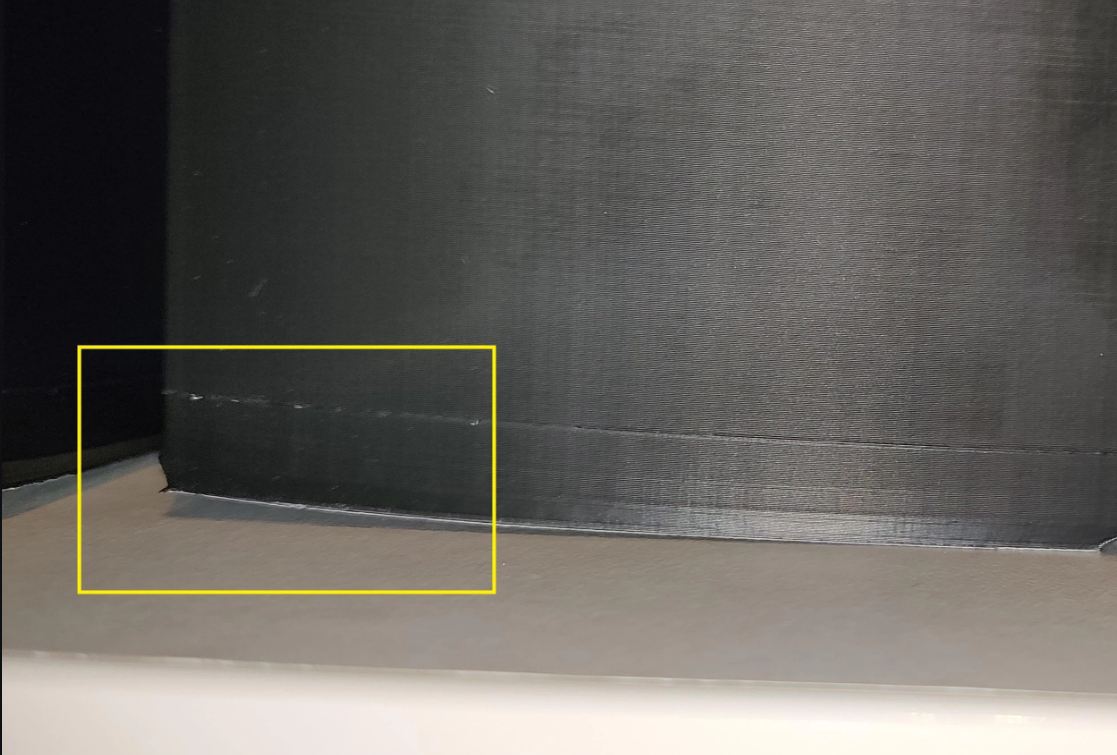

ABS is prone to warping because it contracts significantly as it cools. Without the controlled environment of an enclosure, external factors like drafts, humidity, and temperature changes become significant challenges. Understanding these issues is key to overcoming them.

Key Tips for Successful ABS Printing Without an Enclosure

- Avoid Cooling Fans: Unlike some other filaments, ABS requires gradual cooling. Using fans can cause rapid cooling, leading to warping or cracking. Stick to a no-fan approach unless absolutely necessary. This is one of the most important factors.

- Minimize Drafts: Position your printer in a draft-free area. Avoid placing it near windows, air vents, or HVAC systems. Use barriers if needed to create a stable environment.

- Control Room Temperature: Print in a warmer room. Consistent higher temperatures reduce the risk of warping. Consider using space heaters cautiously to maintain warmth, ensuring safety from fire hazards.

- Monitor Humidity Levels: Keep humidity below 60% to prevent adhesion issues and warping. Use dehumidifiers if necessary and avoid printing in damp areas.

- Optimal Bed Temperature: Start with a bed temperature of 110°C for better adhesion. This reduces the temperature shock between the hot nozzle (around 255°C) and the bed, minimizing lifting or warping. Adjustments can be made once successful prints are achieved.

- Enhance Build Plate Adhesion: Use materials like PEI sheets or apply adhesive aids such as glue sticks for glass beds. Prepare the bed by cleaning it before application to ensure optimal adhesion.

Additional Considerations

- Stable Temperature Control: ABS is sensitive to temperature fluctuations. Maintain consistent heating during printing to prevent issues.

- Alternative Filaments: If ABS proves too challenging, consider PETG. It offers strong parts, fewer fumes, and allows controlled fan usage, providing UV resistance as a bonus.

- Manufacturer Guidelines: While manufacturers often recommend enclosures, success is achievable with careful adjustments and environmental control.

Troubleshooting Tips

If warping persists despite following the tips, consider tweaking bed temperature slightly higher or lower. Check for any remaining drafts and ensure print speeds are optimal for your setup.

Let's sum this up

Printing ABS without an enclosure is a rewarding challenge that can lead to successful results with patience and care. By avoiding cooling fans, controlling environmental factors, and using the right materials, you can achieve professional-grade prints. Remember, persistence is key—keep experimenting until you find the perfect setup for your printer.

Happy printing!