SLS Printer Guide for Home Use

Is SLS for Home Use already there? Yes and No

SLS printers, or Selective Laser Sintering printers, are innovative 3D printing technologies that allow users to create highly durable and intricate objects by sintering powdered materials with a laser. Traditionally used in industrial settings, these printers are now making their way into home use, offering enthusiasts and hobbyists the ability to produce complex designs with ease. Whether you're an artist, engineer, or simply someone looking to explore creative projects, understanding how to use an SLS printer at home can open up a world of possibilities. This guide will walk you through everything you need to know about SLS printers for home use.

Introduction to SLS Printing at Home

Stereolithography (SLS) printing has revolutionized home-based manufacturing by allowing individuals to create intricate, custom 3D objects with ease. Whether you're a hobbyist, an educator, or a small-scale inventor, SLS printers offer unparalleled flexibility in creating precise and durable parts.

Here’s why SLS printing is ideal for home use:

- Versatility in materials: SLS printers can work with a variety of powders, including nylon, glass-filled nylon, and even metal-infused materials, providing options for different applications.

- Customizable designs: With SLS, you can create complex geometries that are difficult or impossible to produce with other printing methods.

- Educational tool: Home SLS printers are excellent for teaching 3D design principles and manufacturing processes to students or hobbyists.

- Cost-effective for small batches: Unlike traditional manufacturing, SLS allows you to print a single part without the need for molds, making it ideal for prototyping or producing small quantities at home.

As technology advances, SLS printers are becoming more accessible and user-friendly, opening up new possibilities for creative and practical projects in the comfort of your own home.

How SLS Printers Work

SLS printers are innovative 3D printing machines designed for creating intricate and durable objects using a powder-based material. Unlike traditional FDM (Fused Deposition Modeling) printers, SLS (Selective Laser Sintering) printers use a laser to fuse powdered materials layer by layer, resulting in high-strength, complex geometries without the need for support structures.

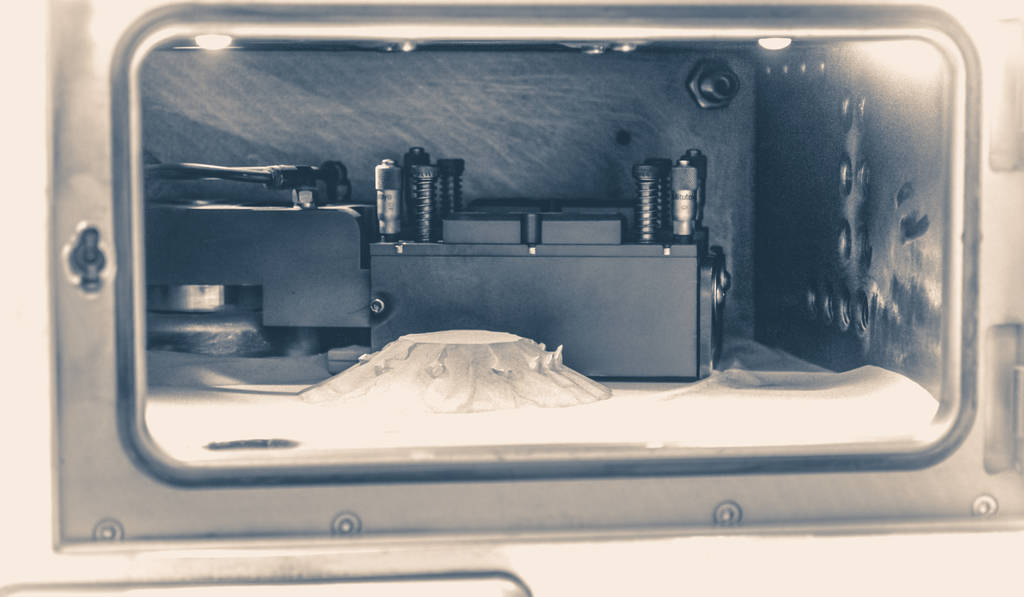

How do SLS printers work? The process begins with a fine powder being spread across a build platform. A high-powered laser then traces the cross-section of the object, selectively sintering (fusing) the particles together to form each layer. Once a layer is completed, fresh powder is added, and the process repeats until the entire object is printed. The unused powder acts as support during printing, which eliminates the need for additional support structures.

For home use, SLS printers are ideal for creating detailed prototypes, custom parts, and artistic designs. They offer exceptional precision and can handle complex geometries that might be challenging with other 3D printing technologies. However, they require specific materials like nylon or metal powders, which can sometimes be costly and require proper handling.

If you're considering an SLS printer for your home workshop, here's a quick guide: start by selecting the right material compatible with your printer. Use software to design or import your 3D model, slice it into layers, and send it to the printer. Once printing begins, allow the machine to complete the process, which may take several hours depending on the object's complexity. After printing, carefully remove the part from the powder bed and finish it by sanding or painting as needed.

Maintenance is crucial for SLS printers. Regularly clean the powder residue to ensure optimal performance and longevity of the machine. Proper ventilation is also essential due to the fine powder particles released during printing. With proper care, an SLS printer can become a versatile tool for your home projects, offering limitless creative possibilities.

Whether you're a hobbyist or a professional designer, SLS printers open up new avenues for creating high-quality, customized products right from your home. Their ability to produce strong, lightweight parts makes them perfect for various applications, from functional prototypes to decorative items. With advancements in technology making SLS printers more accessible, now is an excellent time to explore this exciting 3D printing method.

Advantages of Using an SLS Printer for Home Use

SLS (Selective Laser Sintering) printers are innovative tools designed for creating precise, durable, and intricate 3D printed objects using powdered materials like nylon or metal. Unlike traditional filament-based printers, SLS technology uses a laser to fuse powder particles layer by layer, resulting in high-quality prints without the need for support structures. This makes it ideal for home use, especially for those looking to create complex designs or functional parts with exceptional strength and accuracy.

One of the primary advantages of using an SLS printer at home is the versatility of materials available. With nylon-based powders, users can produce flexible and strong objects that are resistant to breakage. Additionally, the absence of support structures simplifies the printing process, allowing for more creativity in design without worrying about complex setup or cleanup tasks. For hobbyists, educators, or professionals working on small-scale projects, SLS printers offer a seamless way to bring ideas to life with minimal post-processing.

Another significant benefit is durability. Objects created with SLS technology are known for their robustness and long-lasting performance, making them suitable for functional prototypes or custom parts. This feature is particularly appealing for home users who need reliable components for DIY projects or repairs. Furthermore, the ease of use and minimal maintenance required by SLS printers make them a practical choice for everyday home use.

Whether you're crafting intricate models, producing personalized items, or experimenting with creative designs, an SLS printer provides a powerful tool set that combines precision, versatility, and durability in one compact machine. Its ability to handle complex geometries without additional support structures opens up new possibilities for innovation right at home.

Key Features to Look For When Choosing a Home SLS Printer

SLS (Selective Laser Sintering) printers are highly versatile tools that can be used for creating detailed and durable objects at home. However, choosing the right one requires careful consideration of several key features to ensure it meets your specific needs.

**Speed:** Look for a printer with a fast printing speed to minimize production time, especially if you plan to create multiple parts or complex designs.

**Build Volume:** The size of the build chamber is crucial. Ensure it’s large enough to accommodate the objects you want to print but compact enough to fit in your home workspace.

**Cost Efficiency:** Consider the cost per part and the material waste. Some printers use powdered materials, so check if they support recycling or reusing excess powder.

**User-Friendly Interface:** Opt for a printer with an intuitive interface and easy-to-use software for seamless operation, even for less experienced users.

**Material Compatibility:** Check if the printer supports a variety of materials like nylon, metal powders, or ceramic, allowing you to create different types of objects.

**Reliability:** Ensure the printer is built to last with durable components and minimal maintenance requirements.

**Safety Features:** Look for printers with safety features such as automatic shutdown in case of overheating or powder containment systems to prevent dust exposure.

Top Models Suitable for Home Use

Selective Laser Sintering (SLS) is a cutting-edge 3D printing technology known for its ability to create complex geometries without requiring support structures. However, SLS printers are typically large and expensive, making them less common in home environments. While there aren't many consumer-grade SLS printers designed specifically for home use, some compact or hybrid models have emerged that cater to hobbyists and small-scale creators.

One notable option is the Binder Jetting technology offered by companies like Xerox or Creative Mechanism, which combines elements of SLS with other processes, making it more accessible for home users. These printers use powdered materials and lasers to create intricate designs, though they still require careful handling of powders and a controlled environment.

If you're looking for a compact 3D printer that mimics some aspects of SLS without the industrial footprint, consider models like the Formlabs Fuse 1. While not purely SLS, it uses a hybrid process with nylon powder and offers high-resolution prints suitable for home or small studio use.

For most home users, though, traditional FDM (Fused Deposition Modeling) printers remain the more practical choice due to their affordability, ease of use, and smaller footprint. If you're interested in SLS technology but don't have the space or budget for a full-scale machine, exploring hybrid models or powder-based systems could be a good starting point.

Setting Up Your SLS Printer

Setting up an SLS (Selective Laser Sintering) printer for home use requires careful preparation and attention to detail. First, ensure your workspace is well-ventilated, as SLS printers produce fine powder particles during operation. Always wear protective gear, including gloves and a dust mask, to safeguard against potential health risks.

Begin by unpacking the printer and checking all components for damage. Follow the manufacturer’s instructions to assemble the machine properly. Most SLS printers require leveling the build platform to ensure accurate prints. Use the provided tools or software to calibrate the laser focus, as this directly impacts print quality.

Next, load the powdered material into the printer according to the manufacturer’s guidelines. Ensure the powder is evenly distributed and free from clumps. Test the printer with a simple object to verify proper functioning before starting more complex projects.

Regular maintenance is crucial for optimal performance. Clean the printer after each use to remove residual powder, which can interfere with future prints. Inspect belts, pulleys, and other mechanical components periodically to ensure smooth operation.

By following these steps, you can effectively set up your SLS printer at home and start creating high-quality 3D printed objects tailored to your needs.

Tips for Successful Printing at Home

Selective Laser Sintering (SLS) printers are an innovative choice for home use, offering high-quality 3D printing with durable materials. Here’s a guide to help you get started:

**1. Choose the Right Printer:** Look for compact SLS printers designed for home use. They often come with user-friendly interfaces and smaller footprints, making them ideal for limited spaces.

**2. Set Up a Proper Workspace:** Ensure your printer is placed in a well-ventilated area to avoid dust inhalation. A stable surface away from direct sunlight or moisture is essential for consistent performance.

**3. Calibrate Regularly:** Frequent calibration ensures accurate prints. Follow the manufacturer’s guidelines to maintain print quality and longevity of your equipment.

**4. Handle Materials Carefully:** Store powders in a dry, cool place to prevent clumping or degradation. Proper handling minimizes waste and maintains material integrity.

**5. Understand Design Limitations:** SLS printers excel at complex geometries but have size limitations. Design within your printer’s build volume for optimal results.

**6. Post-Process Prints:** Sand or finish printed parts to achieve a polished look. This step enhances durability and appearance, making them ready for final use.

**7. Troubleshoot Common Issues:** Address warping by ensuring even heating and proper support structures. Layer shifting can be corrected with accurate calibration and stable power supply.

By following these tips, you’ll maximize your SLS printer’s potential at home, creating high-quality prints efficiently.

Common Challenges and Troubleshooting Tips

Selective Laser Sintering (SLS) printers are becoming increasingly popular for home use, offering the ability to create intricate 3D printed objects using powdered materials. However, setting up and maintaining an SLS printer at home can present unique challenges that differ from traditional FDM printers.

A common challenge with SLS printers is managing dust. The powdered material used in SLS printing creates a lot of dust, which can accumulate inside the printer or escape into the surrounding environment. To address this, ensure proper ventilation and use a vacuum cleaner to clean up any excess powder regularly. Always wear protective gear like gloves and masks when handling powders to avoid inhaling dust particles.

Another challenge is material compatibility. SLS printers require specific types of powdered materials, such as nylon or metal powders, which may not all be suitable for every printer model. Before purchasing materials, consult the printer's manual or manufacturer to ensure compatibility and optimal performance. Improperly matched materials can lead to poor print quality or even damage to the printer.

Calibration issues are also a frequent problem. SLS printers rely on precise alignment of the laser and powder bed to create accurate prints. Misalignment can result in uneven layers or failed prints. Regularly check and adjust the calibration settings, especially if you notice irregularities in your printed objects. Follow the manufacturer's guidelines for recalibration to ensure optimal performance.

If you encounter unexpected power outages or interruptions during printing, it can ruin the print job. To mitigate this, use a reliable UPS (Uninterrupted Power Supply) and save frequently while printing. Additionally, some printers have built-in backup solutions to pause or resume printing after an interruption.

Troubleshooting tips for SLS printers include:

- Always start with a simple test print to check alignment and powder spread quality before attempting complex designs.

- Clean the laser optics regularly to prevent dust buildup, which can affect print accuracy and cause errors.

- If prints fail repeatedly, reset the printer settings to default or consult online forums for troubleshooting advice specific to your model.

- Keep spare parts like belts, pulleys, or sensors handy, as wear and tear can occur over time.

By addressing these common challenges and following proper maintenance procedures, you can enjoy a smooth experience with your home SLS printer, creating high-quality prints with ease.

Future Outlook

SLS (Selective Laser Sintering) printers are revolutionizing home use with their ability to create intricate, durable, and highly detailed objects directly from digital files. As technology advances, these printers are becoming more accessible, making them a valuable tool for hobbyists, educators, and creative individuals alike.

The future of SLS printing in home settings looks promising. Innovations such as compact designs, user-friendly interfaces, and cost-effective materials will likely expand its adoption. Additionally, advancements in software compatibility and integration with other technologies like IoT could further enhance their functionality, making them an essential part of smart homes.

Despite current limitations such as higher costs compared to traditional FDM printers or the need for specialized skills, SLS technology is paving the way for a new era of home manufacturing. As the market evolves, SLS printers will undoubtedly become more affordable and user-friendly, enabling even more creative possibilities for home users.

For those interested in exploring SLS printing at home, it’s an exciting time to dive into this innovative technology. Whether you're creating custom parts, prototypes, or artistic projects, SLS printers offer unparalleled precision and versatility, making them a powerful tool for any home workshop or creative space.